Will 800-volt systems appear in off-highway applications?

29 November 2023

DPI reports on whether the tech could make its way to commercial trucks and off-highway machines.

While most electric passenger cars use 400 V powertrains, a small number of OEMs have now released models featuring 800 V architectures. These high-power systems offer a series of benefits but there are caveats which must be taken into account, with those issues potentially affecting adoption of the powertrains in other machine types.

For example, producing a high-power architecture is not simply a case of pumping more energy into an existing system; the increase to 800 V brings with it a series of new constraints, requiring a redesign of the battery packs and management systems, the motor/drive and all related components.

Voltage and current primer

In designing EV powertrains, voltage and current are the two primary variables, where (for the same power) more of one means less of another. The end goal is a system which balances the two, while developing the least energy loss.

Such an electrical circuit can be compared to a hydraulic loop, where the water flow rate equates to current, pump pressure is voltage and pipe diameter relates to cable size. Pump fluid into the circuit and the resulting pressure is equivalent to voltage. In a hydraulic loop, a more powerful pump can increase water pressure. A DC/DC converter can achieve a similar increase in voltage, although a battery pack with a higher voltage would deliver additional advantages.

That covers the basics of energy delivery. Looking at recharging levels, these are largely dictated by maximum charger output. Recharging speeds can be increased by raising current levels, but this produces considerably more heat (and related energy loss) in the charger and cables. As such, the goal is to raise voltage delivery and lower current to achieve reduce recharging times. 800 V systems can accept far higher voltages than 400 V equivalents, but more on that a little later.

There are other benefits to higher voltages. A high-voltage architecture can deliver more power to the drive motor(s) without increased current. The lower current level means lighter cables can be used in the wiring harness, resulting in some remarkable weight and cost savings. The reduced heat buildup also helps to extend battery life and improve longevity of other system components.

800 V in passenger cars

Passenger car models using 800 V electrical systems include the Porsche Taycan/Audi e-Tron GT cousins. There’s also the similarly-related Hyundai Ionic 5, Ionic 6 and Kia EV6. Such is the heat-reducing efficiency of these models that unlike cars with 400 V systems, they can perform repeat high-power standing starts with no detrimental effects to the system.

Battery architecture used in 800 V system for the Porsche Taycan (Photo: Porsche)

Battery architecture used in 800 V system for the Porsche Taycan (Photo: Porsche)

But perhaps most importantly (at least from a use-case perspective) is that higher voltage/lower current electrical systems can accept higher kilowatt recharging rates, which returns a significantly shorter charging time.

For example, the Hyundai and Kia models (all use the same powertrain) can be recharged at up to 235 kW. The Porsche/Audi pair increase that to 270 kW. These numbers support vastly improved recharging times. The Porsche/Audi pair can recharge from 5 to 80% in 22 minutes; using a smaller battery pack, the Hyundai/Kia models can go from 10 to 80% in just 18 minutes.

By comparison, the 2021 Lexus UX 300e can only offer a maximum DC recharging rate of 50 kW. Unsurprisingly, this delivers a comparatively slow recharge rate. As more charging points offering the higher outputs supported by 800 V systems come online, the ability to accept those higher charge rates has effectively future-proofed those models.

It should be noted, too, that as car buyers become more familiar with EVs, maximum charge rates will become a key determining factor in vehicle selection – as it could with any other electrically-powered machine. Those with a lower maximum charge rate will likely suffer precipitous depreciation.

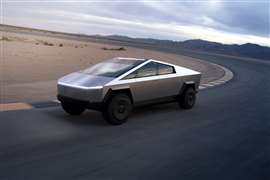

A series of other OEMs, including Stellantis, Toyota, GM and Volvo sub-brand Polestar, are now looking at 800 V tech for their next-gen EVs. As is Tesla, which is reported to be using its first 800 V system on the upcoming Cybertruck. While this will deliver shorter recharging times, it is suspected that reduced material requirements could help improve vehicle profit margins.

Cybertruck is first Tesla passenger model to use 800 V system (Photo: Tesla Motors)

Cybertruck is first Tesla passenger model to use 800 V system (Photo: Tesla Motors)

Tesla’s V4 superchargers deliver a maximum output of 350 kW. While specific numbers are difficult to track down, the Cybertruck is expected to be able to take ‘full advantage’ of that power output. Whether 800 V technology from the Cybertruck is ultimately ported over to Tesla passenger cars, all of which use a 400 V architecture, remains to be seen.

CVs using 800 V systems

Passenger models are not the only vehicles where 800 V architectures are starting to make an appearance. In one such case, Mercedes-Benz has revealed that it will use a high-power system in its new eActros 600 heavy-duty truck.

As with the eActros 300 and 400, ‘600’ refers to the total onboard battery storage capacity. The li-iron phosphate – that’s iron, not ion – packs will have a total capacity of 621 kWh. Using a rigid electric axle with two integrated motors, the eActros 600 is expected to have a single-charge range of about 500 kilometres.

Mercedes-Benz eActros 600 (Photo: Daimler Trucks)

Mercedes-Benz eActros 600 (Photo: Daimler Trucks)

Recharging will be completed at about 400 kW, although reports state that the eActros 600 can support delivery systems of up 1 MW (yes, that’s 1,000 kW). Using this mega charge capacity, the 800 V system will allow a 20 to 80% recharge in ‘well under 30 minutes’, according to the OEM.

Assembly of the eActros 600 is expected to start around mid-2024 at the Mercedes-Benz plant in Worth, Germany. The ‘front box’, the module which holds the control units and high-voltage components for electric models will be delivered from the Mannheim plant, while the electric axles will come from the location in Kassel.

While we’ve already looked at Tesla and how the company is using 800 V systems on its Cybertruck, it should be noted that the OEM has gone one step further with its battery-electric Semi commercial vehicle and fitted a 1000 V powertrain.

As with an 800 V system, the intention is to get the best range performance from its battery packs; Tesla has not published specific numbers, but the Semi is suspected to have between 850 and 1000 kWh of onboard battery capacity. Customers report achieving 1.7 kWh/mile with a fully-loaded truck.

Tesla Semi has 1000 V powertrain with three motors (Photo: Tesla Motors)

Tesla Semi has 1000 V powertrain with three motors (Photo: Tesla Motors)

In addition, the 1000 V architecture can get the best performance/economy from the truck’s tri-motor setup. Borrowed from Plaid variants of the Model S and Model X, on the 6x2 Semi this sees two motors on one axle to support acceleration events, and a single motor on another axle for highway/cruise mode. A four-motor model is likely to be added at a later date to further improve efficiency.

High-voltage in off-highway

As passenger and commercial vehicles are starting to realise the benefits of 800 V (and higher) systems, is there a future for such high-voltage electrical systems in the off-highway sector?

At Bauma 2019, Liebherr unveiled its R 9200 E electric mining excavator. The 210-tonne machine needed 6000 V to power its systems – very impressive. But while mobile, the substantial tether cable delivering the current would be unfeasible for most lesser mobile applications.

“Large machines struggle for every additional ounce of energy during high-load operations,” explained James Dorling, senior consultant at KGP Auto, a powertrain and energy intelligence provider. “While it could be beneficial to have faster charging and moderately improved efficiency [for larger machines], the trend is still towards high-capacity batteries.”

Liebherr R9200 E mining excavator (Photo: Liebherr)

Liebherr R9200 E mining excavator (Photo: Liebherr)

As such, is there an opportunity for 800 V systems to feature on more conventional backhoes and tractors?

At CNH Industrial, Mario de Amicis, head of the Electrification Portfolio Management, says 800 V systems provide unique advantages for off-highway and agricultural platforms; machines which will require a diverse range of systems to address to the current portfolio powered by 25 to 500 hp internal combustion engines.

“[800 V systems] will translate to a better customer experience by enabling much faster charging times, higher operating ranges and extended machine availability,” he noted.

“In addition to the advantages seen in the automotive market, agricultural equipment also powers implements. At the higher voltage ranges, the power transfer to the e-implement supports a higher power transfer, better energy management and increased efficiency.”

But, as de Amicis noted, this comes with some related challenges, already being managed in the auto sector.

“800 V systems come with the challenges of a limited supplier base, increased safety requirements and higher component cost. But the situation will likely become more favourable with automotive growth in the field – in my opinion, 800 V will become a standard for the agricultural industry in the near future.”

Technology adoption

As with hydrogen powertrains, wider adoption of 800 V powertrains in any application (on- or off-highway) will be limited by related part availability. And as with H2 fuel dispensers, which remain a rare sight, there are still only a limited number of chargers which can deliver recharging levels to take advantage of 800 V architecture.

But in one case at least, the speed of technology adoption appears to have caught a major OEM by surprise.

Volkswagen AG, owner of both Porsche and Audi, elected to not roll out the 800 V architecture developed from the ground up for the Taycan and e-Tron GT across its own EV model ranges due to part supply and cost issues. But with an 800 V system, the Hyundai Ionic 5 offers twice the potential charging performance of the VW ID4 – while both models retail at about the same price.

Perhaps VW didn’t realise how fast other carmakers would be to adopt 800 V tech. But its attempts to limit cost and retain such tech for its premium brands could have lasting consequences for the market performance of VW’s own EV models.

Arnold Fenocchi, CEO of Artis Magnetics, assisted with producing this article.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM