The Rust Belt start up looking to ‘do a Tesla’ on compact construction equipment

08 July 2025

US-based start-up HeavyTech is looking to make the mini excavator equivalent of a Tesla. The Indiana-based firm says its ability to pursue radical design changes and challenge entrenched assumptions will allow it to take on established North American manufacturers as well as European and Chinese rivals in the EV compact equipment sector. Chad Elmore meets the founders and finds out how they plan to do it.

Davide De Silvio and Mike Terzo (Photo: HeavyTech)

Davide De Silvio and Mike Terzo (Photo: HeavyTech)

From their offices in Fort Wayne, Indiana, USA, the founders of start-up Heavytech are constantly reminded of a long-passed heyday of US manufacturing.

Once a booming manufacturing town, known for supplying nearly 90 per cent of North America’s magnet wire market, like many towns in the so-called Rust Belt, over the last forty years it has been hit hard by a loss of blue-collar manufacturing jobs.

Since then, the city has been working hard to diversify its economy by encouraging a range of other industries including distribution, transportation, logistics, data centres and battery manufacturing.

Battery-powered and hybrid compact construction equipment

Since May these have also numbered Heavy Tech, a start-up founded by a group of industry veterans is seeking to produce battery powered and hybrid compact construction equipment.

“I am very excited about HeavyTech and what it can mean to this area and the markets it will reach,” says Nicholas Darrah, co-founder and board member of HeavyTech Inc who is also vice president of Partnerships & Government Relations for Northeast Indiana Regional Partnership (NEI), a public-private regional economic development organization.

Before launching HeavyTech, Mike Terzo has been working on three compact machines for agricultural, landscaping and construction applications, including this compact track loader. (Illustration: HeavyTech)

Before launching HeavyTech, Mike Terzo has been working on three compact machines for agricultural, landscaping and construction applications, including this compact track loader. (Illustration: HeavyTech)

“HeavyTech is going to be something that, 20 years from now, I can tell my grandkids that was I was part of, and it will be putting food on the table for generations of families.”

The company, which officially launched in May, plans to manufacture a line of compact construction machines — including track loaders, mini excavators and articulated loaders — built on a modular platform that enables users to switch between battery-electric and diesel-hybrid power.

The initiative is being led by Mike Terzo, an engineer and entrepreneur best known for his previous venture, Terzo Power Systems, which developed intelligent electro-hydraulic systems to improve energy efficiency in heavy-duty machinery.

“When we get into electro-hydraulic power-on-demand technology it’s very powerful. We only spin the pump when you’re doing a work function, and then we control the pump with an electric motor,” says Mike Terzo, co-founder and CEO of HeavyTech, a US start-up looking to make battery-electric and hybrid compact construction equipment. “That’s our core powertrain technology, and I’ve been working on it for almost 15 years. We’re very excited to show it to the industry.”

HeavyTech’s launch comes at a time of mounting pressure on the construction and equipment sectors to reduce emissions and improve efficiency.

Europe, in particular, has led the regulatory push for electrification, but adoption is accelerating globally.

While major OEMs have begun introducing electric models, Terzo argues that start-ups like HeavyTech are better positioned to pursue radical design changes and challenge entrenched assumptions.

The company is funding its early development through a Regulation Crowdfunding campaign registered with the U.S. Securities and Exchange Commission — a mechanism that allows it to raise capital while openly marketing its vision. Proceeds are being used to build prototype chassis and order key components.

HeavyTech’s modular approach is designed not only to serve multiple markets but to foster industry-wide collaboration. “The whole industry really needs to understand how to develop and integrate this technology on the electric and hybrid front, and that’s part of what we’re doing with HeavyTech,” says Terzo. “We’re launching this company and will prove the products in front of the entire industry. We want everybody to share this experience and see what we’re doing because, ultimately, a rising tide lifts all boats in the off-highway industry.”

Attracting attention beyond North America

The company has attracted attention beyond North America. Davide De Silvio, a former executive at FPT Industrial and Liebherr, has joined as Chief Commercial Officer and is leading European operations from Italy. He said the model — modular electrification paired with a focus on operator needs — is well suited to European markets, which are often characterised by more stringent emissions targets and dense urban environments where compact machines are in high demand.

“The model is replicable in Europe, so from day one we have an international mentality,” says De Silvio. “Our technology will also get a lot of traction in Europe. Offering a mix between hybridization and electrification is very appealing, and I can see HeavyTech marketing not only the machines but the powertrain itself.”

While HeavyTech has global ambitions, it is also positioning itself as part of a broader movement to reinvigorate advanced manufacturing in the US. Industrial development has become an increasingly important policy lever in Washington as geopolitical tensions and supply chain vulnerabilities prompt a rethink of globalised production models.

Darrah sees HeavyTech’s trajectory as emblematic of a wider reshoring trend.

““We’re working to start original manufacturing in the United States with technology developed in the United States,” he says. “Our primary competitor outside of this space is China, and they’re not going to stop developing this technology. Someone’s got to do it, and if the traditional OEMs are not, because they don’t have the risk tolerance or incentive to do, we’ve got the ball rolling here.”

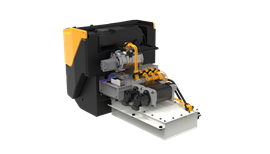

HeavyTech’s machines will be designed so the powerplant can be swapped quickly, between a lithium-ion battery pack to a hybrid. (Illustration: HeavyTech)

HeavyTech’s machines will be designed so the powerplant can be swapped quickly, between a lithium-ion battery pack to a hybrid. (Illustration: HeavyTech)

Much of HeavyTech’s early engineering work has been conducted in home workshops and temporary spaces, but the founders are eyeing a permanent headquarters and assembly site at a mixed-use industrial redevelopment — one of the largest in the U.S. — on the site of a former GE manufacturing campus. The facility now houses corporate offices, education centres, and lab space, with further phases set to include an advanced manufacturing institute.

The company aims to produce two to three working prototypes within the next year and begin vehicle demonstrations by late 2025 — a timeline that puts it on a collision course with the next generation of electric models from incumbent manufacturers. Terzo is confident that HeavyTech’s architecture-first approach and in-house firmware development will set it apart.

“We have really looked at how we design and develop these pieces of equipment, and we want to launch HeavyTech in a way that is very industry collaborative,” he says.

The founders also argue that their method of financing — and by extension, their governance model — allows for greater transparency and responsiveness to market needs. “Traditional funding mechanisms in our sector tend to stifle risk and slow innovation,” Terzo said. “Our approach has been open, inclusive, and built around shared belief in the mission.”

Whether HeavyTech can scale and survive in a capital-intensive industry dominated by global players remains to be seen. But for now, the company’s model — modular, electric, and collaborative — reflects a broader shift underway in the construction equipment landscape, where old paradigms are giving way to more agile, digitally enabled alternatives.

“Personally, I’m calling this my YOLO [you only live once] run,” said Terzo. “We have to try something really ambitious in our industry, and I think the time is right — strangely enough. The cooling of the EV market is helping the story. People are sold on the benefits of electric off-highway equipment, and now they want real business models. They want real metrics around what you’re selling — and it would be bad if we were trying to capitalize on the institutional investment market right now.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM