The company using written-off Tesla batteries to power construction sites

25 June 2025

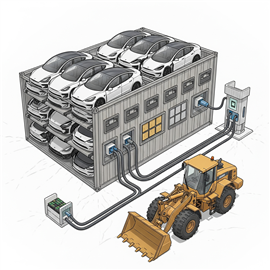

UK-based Allye Energy is repurposing salvaged Tesla battery packs to create mobile fast-charging units for construction sites — giving EV batteries a meaningful second life, cutting diesel emissions on jobsites and enabling the company to compete in terms of cost with its Chinese competitors. Chief operations officer Alistair McNeil, tells Lucy Barnard, how they are doing it.

Image: Gemini (using AI)

Image: Gemini (using AI)

Alistair McNeil, chief operations officer of battery technology start-up Allye, is not inclined to mince his words. “If we’re shredding batteries that have got usable energy left in them,” he says, “then I’m afraid we all want lining up and shooting. It’s not on. It’s not good.”

The forthright Brit is reflecting on the large number of electric vehicle (EV) battery packs sent for premature destruction each year—often simply because insurers have written off the car. In many cases, he says, the batteries themselves are still in good health.

“Recycling is improving, but it’s not where people think it is in terms of efficiency,” he says. “If we can extract five or ten more years of use from these batteries first, that’s a much more sustainable outcome.”

Allye’s proposal is taking EV batteries from written-off vehicles—primarily Teslas, Kias and Hyundais, and repurpose groups of them, with some clever electronics, as large truck-sized power units capable of powering up heavy machinery for construction sites in the place of – or along side – a diesel generator.

The Max 1000 on site for Collins. Photo: Allye

The Max 1000 on site for Collins. Photo: Allye

“We’ve got really good relationships with most of the suppliers or vehicle dismantlers in the UK and with OEMs,” McNeil says. “We test each battery. Our software can communicate directly with the battery management system, so it checks the cell voltage, temperature, internal resistance etc. It makes sure that the BMS is communicating well. It’s either a big green yes or a big red no. If it’s a no then the battery gets sent away to get shredded but if it’s a yes then we bring the battery back and run it through a full charge and discharge cycle so we can determine the true state of health of the battery and how long it will last in the system.”

This, Allye says, not only means that not only is the whole process far greener than producing new batteries would be but it is also cost effective, allowing Allye to make BESS units at a similar price to those imported from China and at roughly half the prices charged by its European competitors.

Moreover, Allye also says that this means that its batteries have already passed the rigorous validation and certification required for road use. McNeil says the batteries Allye uses have been tested to European Union Reg 100.3 and United Nations 38.3 standards. These batteries have already been through thermal, vibration and crash tests.

“We’re not just wiring up loose cells and hoping for the best,” McNeil adds. “You can’t easily replicate that kind of quality assurance with bespoke builds.”

“If the batteries fail, we’re not interested,” McNeil says. “We don’t get the battery here and start taking covers off and replacing cells. That’s partly because it’s dangerous work and our insurance premiums would go through the roof but also because there’s a glut of batteries out there - but not many people know how to interrogate them. The skills, the standards, the data sharing—it’s all still evolving.”

For Allye, Tesla batteries are the power source of choice.

“We very purposely focused on Tesla batteries first,” McNeil says. “Not the model S or the model X because they were the first offs. By the time they got to the model 3 and the model Y they had done a lot of learning. The batteries are pretty phenomenal. These batteries are still being used and they are still one of the market leaders.”

Alistair McNeil. Photo: Allye

Alistair McNeil. Photo: Allye

Founded in 2022 by former Fiat, McLauren and Jaguar Land Rover executive, Jonathan Carrier, the London-based company has developed a mobile battery energy storage system (BESS) designed to serve sectors with constrained or unreliable access to power—chief among them construction.

Allye effectively repackages these sets of repurposed batteries and connects them up to its own proprietary energy management system which enables them to be used on site.

“A battery is just a big dumb block of energy. The smart side of it comes in how you manage those batteries,” McNeil says. “So, we’ve got the battery management system (BMS) within the batteries – that’s all carried over because it’s certified and signed off. Then, sitting on top of all the batteries, whether it’s four in a unit or 12 or 20, is our energy management system which communicates with the BMS in the batteries. That’s the crucial bit because it tells the batteries what they need to do and without that they just sit there as energy.”

As well as measuring the health of each of the individual batteries in the unit and managing them so that they converge to a common state of health over time, McNeil says the software is starting to predict when maintenance is needed.

“The more batteries we test, the more data we get because we see exactly how many miles they have done, how many times they have done fast charging etc. You learn a whole lot from that and that feeds into out algorithms and our data scientists are able to build up predictions,” he says.

Last month, Allye agreed a deal with UK-based groundworks contractor Collins Earthworks to become the first customer for its MAX1000, a BESS unit the size of a truck with a total storage capacity of nearly 1MWh.

Collins has been using the unit’s 240kW DC fast charging to recharge four Volvo FMX electric transport trucks.

Allye says the unit is capable of charging the batteries of trucks like this from 20% to 80% in just over an hour. Moreover, the company says it can fully recharge a typical electric crawler excavator—fitted with a 260kWh battery—in under 25 minutes and fully charging five large excavators in a single day.

“When we talk about ‘fast charging’ in cars, people often think of rates at 3C or 4C—three or four times the battery’s capacity,” McNeil explains. “But with construction plant, even at 480kWh, we’re still under 1C. You’re not degrading the battery—you’re tickling it.”

Allye also says it has sent two units to Irish energy rental firm Horizon Offgrid Energy Hire and the company recently put in an order for two more. The company specialises in supplying generators to power tower cranes and has been in discussions with other UK rental firms.

Photo: Allye

Photo: Allye

For contractors, the cost implications are significant. According to Allye, operators can save up to £2,500 per week in diesel costs alone, with further reductions from lower maintenance burdens and the avoidance of expensive grid upgrades. The company’s systems use a combined charging system (CCS) with outputs ranging from 240kW up to 640kW, and longer cables designed for industrial use with large vehicles and equipment.

The cost of purchasing a Max 1,000, McNeil says, starts at £250,000 (US$336,000) although this depends on the configuration and what the unit is going to be required to do. Allye’s smaller Max 300 unit starts at £75,000 (US$100,000).

And, McNeil says, Allye’s energy management systems, individual packs are installed independently, each with their own inverter and controls, enabling simultaneous charging and discharging across different units.

Systems include an artificial intelligence forecasting platform that analyses usage patterns, weather conditions and operational schedules to optimise charging profiles in real time.

“It’s not just a battery in a box—it’s an intelligent energy management system,” says McNeil. “We can predict demand, smooth peak loads, and dynamically allocate energy where it’s needed most.”

“We’re not reinventing the battery,” he adds. “We’re just making better use of the ones we already have.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM